Competitiveness, efficiency and sustainability

An all-in-one Project!

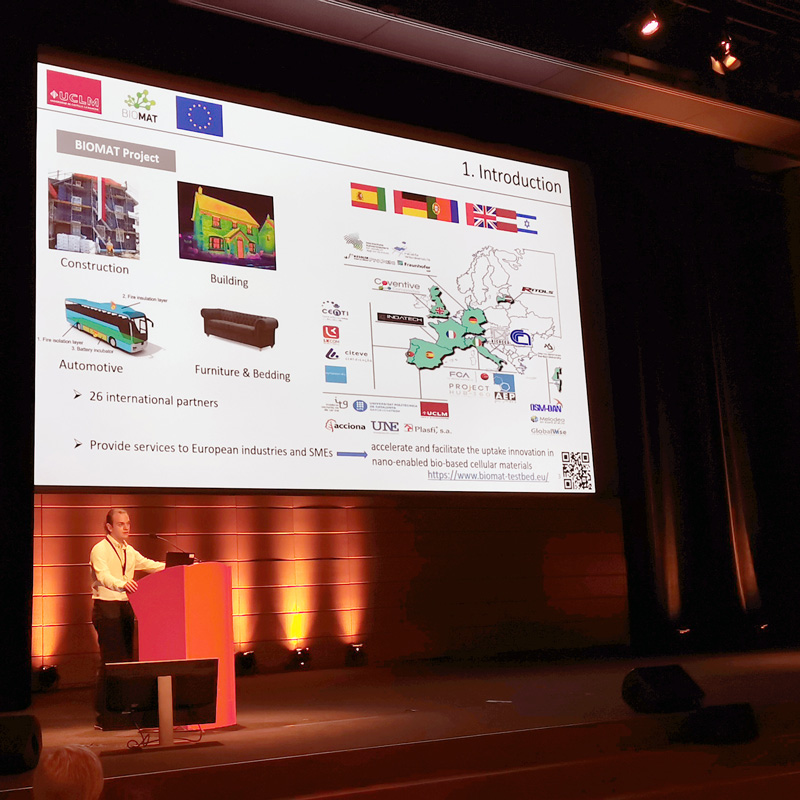

Meet BIOMAT’s 26 international partners

Portugal, Germany, France, Italy, Latvia, Spain, UK and Israel

To be sustainable is to accelerate innovation!

Get ready for the BIOMAT revolution.

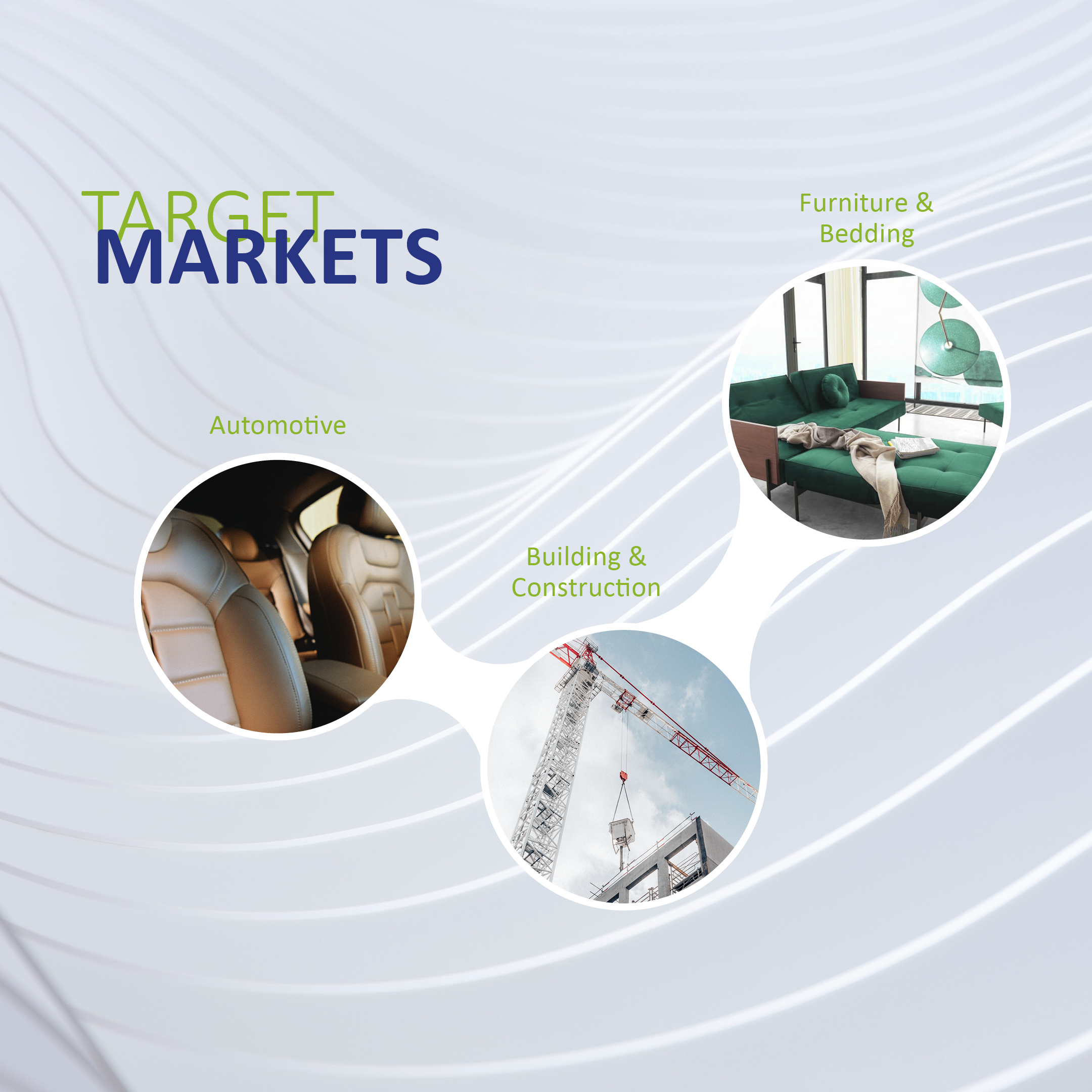

Once the European Union is among the world’s biggest producers of motor vehicles, BIOMAT aims to make the automotive industry more environment-friendly! This Project paves the way towards developing highly innovative, safe, and sustainable interior car parts such as seat cushions, headrests, and steering wheel, using the newly developed novel soft and semi-rigid bio-polyurethane (bio-PUR) foams. This will further result in improved reliability, durability, and reduced life-cycle costs.

BIOMAT’s researchers will develop nano-enabled bio-based rigid and semi-rigid polyurethane (PUR) foams from bio-polyols and bio-nanofillers to scale-up and produce lining road tunnel waterproofing and molded insulation panels and/or sandwiches with, among others, high heat-insulation and noise insulation capabilities, flame retardancy reduced energy consumption materials for the construction and building industries.

BIOMAT is working on a new generation of chairs, sofas, and mattresses in the Furniture and Bedding industries. Single-bed, childbed mattresses and upholstered sofas and chairs based on nano-enabled soft and semi-soft bio-polyurethane foams, with a structure based on open-cell that increases density, durability, flexibility, strength, fatigue resistance, form stability, air permeability, and body support. These foams are also Volatile Organic Compounds (VOC) free. This is the Project Consortium’s main goal for the Furniture & Bedding Industry, in response to the unsustainable petroleum-based PUR foams used in typical soft and semi-soft foams applications.

Once the European Union is among the world’s biggest producers of motor vehicles, BIOMAT aims to make the automotive industry more environment-friendly! This Project paves the way towards developing highly innovative, safe, and sustainable interior car parts such as seat cushions, headrests, and steering wheel, using the newly developed novel soft and semi-rigid bio-polyurethane (bio-PUR) foams. This will further result in improved reliability, durability, and reduced life-cycle costs.

BIOMAT’s researchers will develop nano-enabled bio-based rigid and semi-rigid polyurethane (PUR) foams from bio-polyols and bio-nanofillers to scale-up and produce lining road tunnel waterproofing and molded insulation panels and/or sandwiches with, among others, high heat-insulation and noise insulation capabilities, flame retardancy reduced energy consumption materials for the construction and building industries.

BIOMAT is working on a new generation of chairs, sofas, and mattresses in the Furniture and Bedding industries. Single-bed, childbed mattresses and upholstered sofas and chairs based on nano-enabled soft and semi-soft bio-polyurethane foams, with a structure based on open-cell that increases density, durability, flexibility, strength, fatigue resistance, form stability, air permeability, and body support. These foams are also Volatile Organic Compounds (VOC) free. This is the Project Consortium’s main goal for the Furniture & Bedding Industry, in response to the unsustainable petroleum-based PUR foams used in typical soft and semi-soft foams applications.

BIOMAT is a highly innovative European Project which aims to revolutionize the Building, Construction, Automotive, Furniture & Bedding markets. How?

By transforming the typical PUR foams into a sustainable, cost effective, biobased and nano-enabled alternative. Through BIOMAT Project, we will establish an Open Innovation Test Bed that will be the key to a more sustainable Europe.